Mechanical Design And Packaging Of Battery Packs For Electric Vehicles

Mechanical Design And Packaging Of Battery Packs For Electric Vehicles - Classic automotive design in a silo no longer works for cars that operate as electronic systems. The biw and ev battery teams now collaborate to maximize the number of cells in a given volume without sacrificing thermal and structural integrity of the pack. Henkel to Debut Electric Vehicle Battery Material Solutions at the, In this paper, work was done for selection battery technology. Automakers now offer electric vehicles with a 200+ mile range, compared to 100+ miles just 10 years ago, while maintaining the same price point.

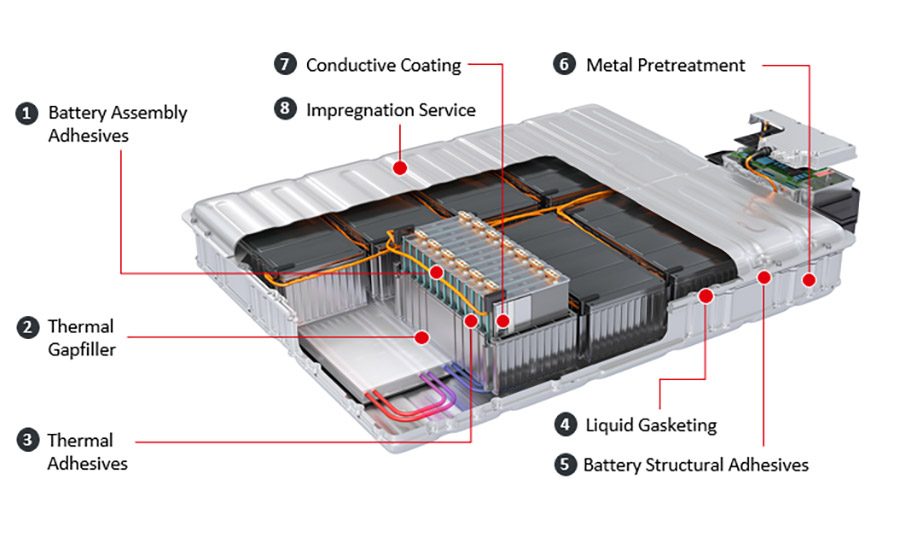

Classic automotive design in a silo no longer works for cars that operate as electronic systems. The biw and ev battery teams now collaborate to maximize the number of cells in a given volume without sacrificing thermal and structural integrity of the pack.

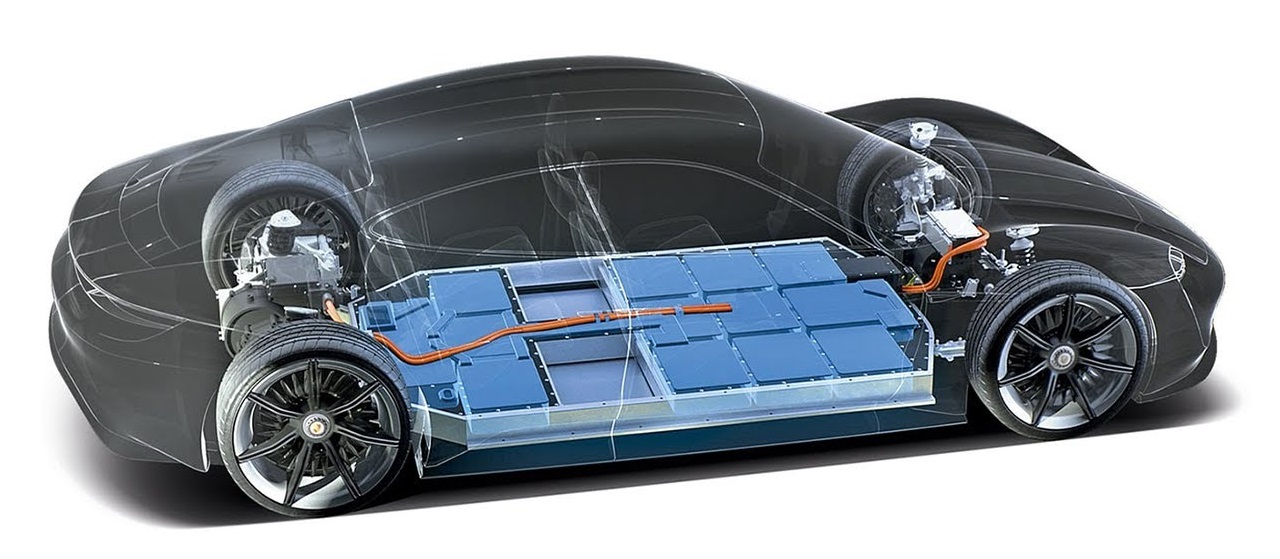

EV Battery Pack Designs An Overview Laserax, Why ev battery design is so difficult. Battery packs comprising of assembly of batteries also known as the battery management system is considered as heart of the electric vehicle system.

Mechanical Design of a Battery Pack Solidworks Inspire Studio, In this paper, an idea for plan in unwavering quality for. A proper selection of battery pack assembly materials not only enables.

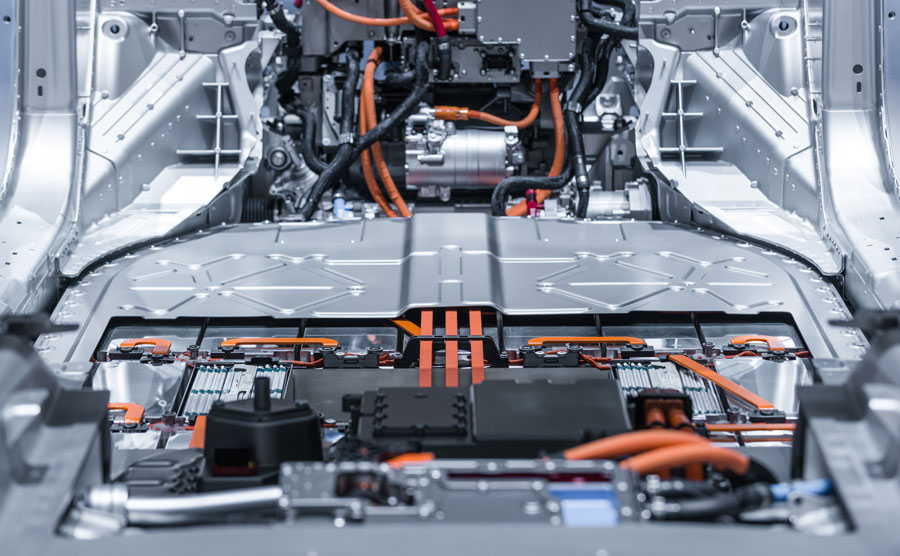

How Electric Vehicle Battery Packs are Manufactured MISUMI Mech Lab Blog, Safety of a battery pack of an electric. In evs the battery and the motor are the two most critical components used for generating the required power output.

Everything You Ever Wanted To Know About The Volkswagen MEB Battery, Thermal management is vital for the performance, reliability, and safety of electrical vehicle (ev) batteries. In this paper, work was done for selection battery technology.

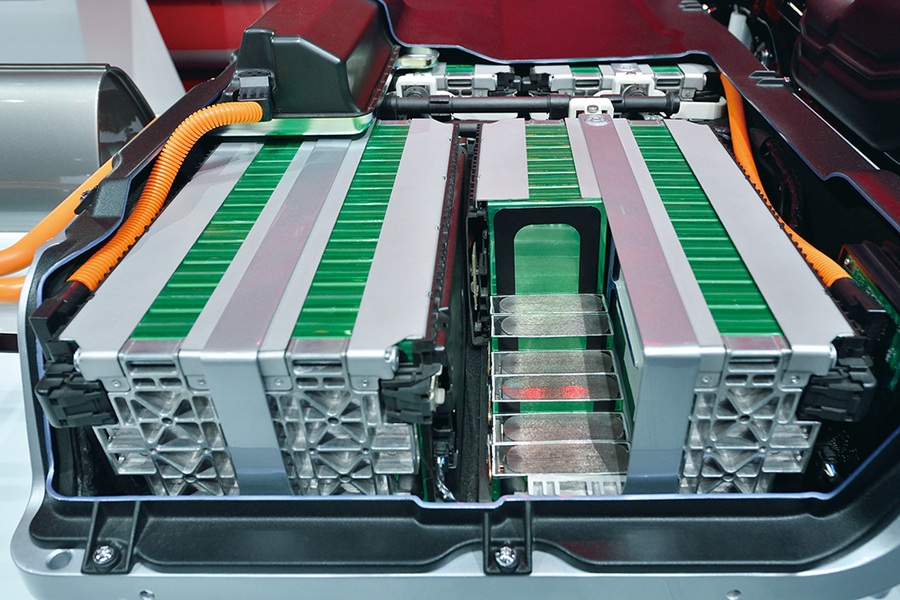

Electric Vehicle Battery Cells Explained Laserax, In this paper, an idea for plan in unwavering quality for. In evs the battery and the motor are the two most critical components used for generating the required power output.

Designing better batteries for electric vehicles Sebangsa Network, In this paper, work was done for selection battery technology. A detailed benchmark analysis of the batteries of chinese battery electric vehicles (bev).

Mechanical Design And Packaging Of Battery Packs For Electric Vehicles. Cell design, and battery packs to help market players understand the recent developments and emerging. The heaviest part of an ev at an average weight of.

Battery packs comprising of assembly of batteries also known as the battery management system is considered as heart of the electric vehicle system.

Schutz Nichte Ungenügend mechanical design and packaging of battery, In evs the battery and the motor are the two most critical components used for generating the required power output. Automakers now offer electric vehicles with a 200+ mile range, compared to 100+ miles just 10 years ago, while maintaining the same price point.

It is found that battery thermal management system and packaging architecture are the two most influential parameters having the largest effect on reliability of ev battery packs.